1) Thermal fatigue, caused by the heat stress resulting from the repeated cold and hot shocks during the die-casting process, gradually leading to the formation of cracks. Most cracks are in a grid shape, also known as turtle cracks, or in a radial shape. These micro-cracks on the surface of the die-casting molds can generally be repaired.

If the thermal fatigue cracks penetrate into the matrix, the mold repairing process can cause the die-casting molds to have excessive dimensions, or due to mechanical stresses or thermal shocks during the die-casting process, the cracks expand into macroscopic cracks, leading to the failure of the die-casting molds.

2) Serious brittle cracking, which first forms large macroscopic cracks and then quickly expands, leading to brittle cracking and failure. The reasons for this are numerous, such as improper die-casting operations resulting in mechanical overload or thermal shock, poor processing quality weakening the load-bearing capacity of the die-casting molds, unreasonable die-casting mold designs leading to stress concentration, etc. The lack of toughness in the die-casting mold material is an internal cause of brittle cracking.

3) Corrosion, during the die-casting process, the molten metal is injected into the die-casting molds cavity under pressure. Under certain conditions, a reaction can occur between the molten metal and the mold, causing the mold material to dissolve, which is essentially a combination of erosion and corrosion. The main influencing factors are the temperature and composition of the cast alloy, the mold design, and surface treatments.

4) Collapse refers to the sinking of the die-casting molds during the die-casting process, or the collapse of the parting surface. This is caused by the too low thermal strength of the die-casting mold material. The higher the die-casting temperature, the greater the possibility of collapse.

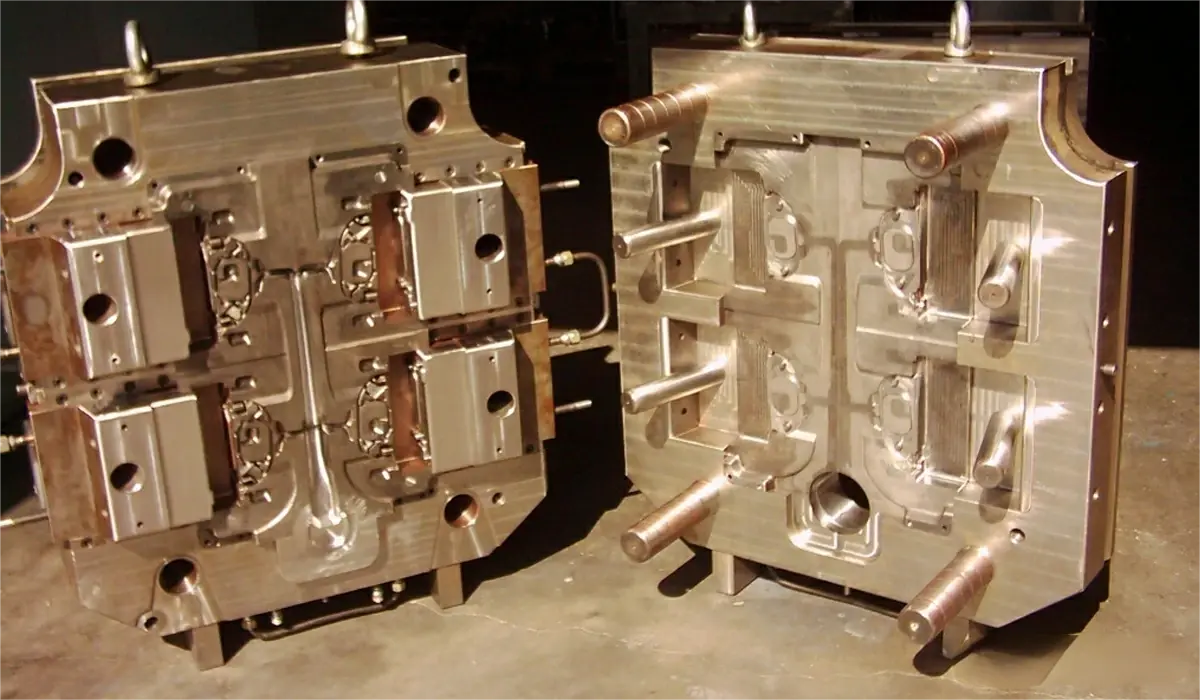

The service life of the die-casting molds is closely related to the material of the die-casting molds. The die-casting mold components are mainly divided into components in contact with the molten metal, sliding fit components, and mold structure components.

The die-casting mold cavities and gating system components directly contact the high temperature, high pressure, and high-speed liquid metal during the high-pressure die-casting production process. They are subjected to direct scouring, wear, high-temperature oxidation, and various types of corrosion on the one hand and, on the other hand, due to the high efficiency of production, the die-casting molds temperature rises and falls dramatically, forming periodic changes. Therefore, the die-casting mold steel requires high thermal fatigue resistance, thermal conductivity, good wear and corrosion resistance, and high-temperature mechanical properties.

The selection of die-casting mold materials mainly depends on the temperature of the cast metal and the kind of cast metal. The higher the temperature, the more severe the damage and wear of the die-casting molds.

Since the various components of the die-casting mold work under different conditions and are subjected to different impacts and wear from the cast metal, the hardness requirements for the die-casting mold should be different according to the use of the components and the type of cast metal. For example, for components with severe wear, higher hardness is required, and for components that work under heating conditions, higher thermal fatigue performance and high-temperature performance are required.

Call us on:

Call us on:  Email Us:

Email Us:  Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,

Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,