1. Final product

The application of the final product is one of the most important aspects to be considered before rapid 3D printing. In some cases, the prototype needs to replicate the final product in size, function or aesthetics.

In other cases, the prototype may be just a single component that needs to be checked for suitability for assembly. More simply, before choosing the basic industrial design, a conceptual model can demonstrate the shape and feeling of the product to the user.

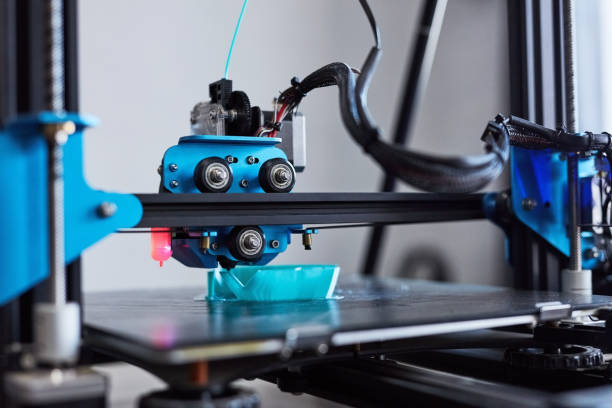

2. 3D printing technology

According to the type of 3D printing prototype and its application, engineers need to select the corresponding 3D printing technology. For functional prototype printing, Fused Deposition Modeling (FDM) is a common technology. FDM is also applicable to parts with product characteristics above 100 microns.

For prototype printing focusing on beautiful appearance, technologies such as stereo lithography (SLA) or polyjet can be used. In some cases, the best prototype effect can be obtained by combining additive manufacturing and subtractive manufacturing technology.

3. Design elements

In 3D printing prototype, design elements such as wall thickness, waterproof design and multi shell need to be considered, as well as the minimum product size corresponding to different types of 3D printing technology.

This is similar to the factors you need to consider when using other manufacturing technologies. However, compared with using subtractive technology, 3D printing can obtain unprecedented geometric degrees of freedom.

1. PLA

PLA has become one of the most commonly used materials in FDM 3D printing because of its low cost and easy to use characteristics. In fact, for those familiar with 3D printing prototype engineers, PLA may be the first material they use. It is widely used in products with a size of more than 100 microns, and PLA is also used in large-scale product manufacturing, so as to optimize the cost of prototyping.

2. ABS

ABS is often used in mass production of plastic products, which makes it a very popular prototype material. Although ABS is difficult to print due to its easy warpage, engineers can overcome this problem by using 3D printers with controllable printing environment. It also applies to prototypes that require post-processing. ABS is relatively easier to carry out post-treatment than PLA.

3. PETG

Due to its chemical resistance, PETG is another material commonly used in consumer goods and packaging, such as food and beverage packaging, lubricants and soaps, and dental products. Companies producing such consumer goods need to constantly update and design new packaging to attract customers' attention or improve users' experience of products. Therefore, 3D printing prototype is very important to renew the appearance of injection molding oem so as to attract more customers.

4. PC

PC or polycarbonate is becoming more and more popular in different industries such as electronic components, automobile, medical treatment and consumer technology. They have transparency, high durability and scratch resistance, and are suitable for mass production. Like the above common materials, the need for PC to actually create 3D printing prototypes is also obvious.

Call us on:

Call us on:  Email Us:

Email Us:  Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,

Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,