A multi-cavity mould is known as a mould with multiple cavities. The multi-cavity mold consists of a multi-cavity of different plastic parts.

Though multi-cavity injection molding process may be much more complex than others such as insert injection molding process, it is still popular as the improvements of production efficiency and cost-efficiency. As a leading multi-cavity mould manufacturer, GM-TECH provides you with high-grade multiple cavity mould to meet the needs of high-yield, high-precision products.

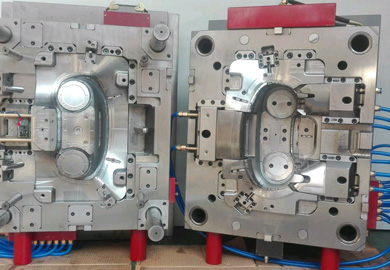

Multi cavity molds contain more than one cavity of the same part. It’s able to produce many parts per injection molding cycle with high-volume production. Here are some major features of a multi-cavity mould.

More parts can be manufactured by the same mold within the cavity.

Generally speaking, a multi-cavity mould is at a lower custom plastic molding cost than a single cavity mould.

The requested number of components will be finished faster due to the shorter lead time per batch.

More efficient use of the cycle time

The processes of multi-cavity mould are more stable

It keeps flow balance of cavity injection molding

Part material | PP |

Cavity | 16 |

Runner:16 drops hot runner | |

Mold accuracy | + / - 0.02 |

Mold steel | 1.2343 |

Mold blank steel | 1.1730 |

Mold life | 100W |

Mold standard | HASCO |

Mold structure | 12 lifters |

Exporting country | Australia |

Lead time | 5 weeks |

Mold quality customer satisfaction | 100% |

FAI pass rate | 100% |

Project cooperation service customer satisfaction | 100% |

The basic manufacturing process of multi-cavity mould by GM-TECH, a professional company specializing in moulding products, are as follows:

Plastic is melted in a plastic injection molding machine and then injected into a mold under high pressure. The material is cooled and solidified inside the mold, then the two halves are opened and the product is removed. The technology produces plastic products with predetermined fixed shapes.

To simplify production, the parts of multi-cavity mould that function in the plastic injection molding process must be carefully designed. Products made using multi-cavity injection molding machines are first designed by industrial engineers or designers. The die manufacturer takes into account all the key conditions: the materials used in the final product, the function of the product; In addition, the material of the mold, and the characteristics of the multi-cavity injection molding machine.

Call us on:

Call us on:  Email Us:

Email Us:  Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,

Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,