Automotive plastic mould is a general expression of moulds that make all the parts on a vehicle. It can be divided into several types of moulds such as injection mould, stamping dies, forging dies, casting wax dies, glass dies, and so on.

Automotive plastic injection molding is becoming popular because of the auto parts are the foundation of automotive development. As one of the professional automotive plastic injection molding company, GM-TECH aims at providing high-quality automotive plastic parts mould and service at a reasonable price.

Rapid Prototyping

Quick production of automotive injection molding plastic prototypes helps to shorten the time spent in developing part designs.

Cost-Effectiveness

One injection mold can be used to make thousands of parts. GM-TECH gives you access to a full array of injection molding services.

High Efficiency

Automotive injection molding ensures that your contract manufacturing of plastic parts can shorten your time in the market and meet your clients’ expectations.

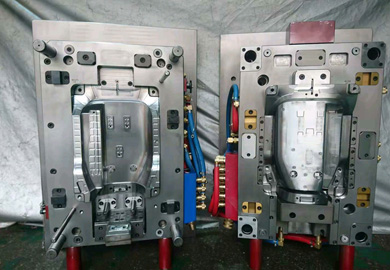

Part material | PBT |

Cavity | 1 |

Tool Accuracy | + / - 0.02mm |

Mould steel | 738H |

Mould steel | 1.1730 |

Mould life | 30W |

Mould standard | HASCO |

Mould structure | 1 slide |

Exporting country | Italy |

Leadtime | 6 weeks |

Mould quality customer satisfaction | 98% |

FAI pass rate | 96% |

Project cooperation service customer satisfaction | 98% |

The process cycle of automotive plastic injection mold making itself includes the following steps:

1.Place the mold into the automotive injection molding machine. An injection molding machine is used to close the mold during automotive plastic injection molding by means of a clamp.

2.The granule or pellet-shaped plastic is fed into the automotive injection molding machine.

3.Then the machine heats the plastic until it becomes a liquid. The automotive plastic injection molding machine nozzle then pours the melted plastic into the mold.

4.At this point the mold cavity is filled with plastic liquid. The liquid cools to form a solid product.

5.Finally, the ejector (linked to the ejector system) removes the cooled product from the machine into finished parts.

Call us on:

Call us on:  Email Us:

Email Us:  Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,

Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,