Industry diversity and multiproject management makes us your strong partner. Punctuality, quality and efficiency are key to successful project work. Our team is sure to meet your requirements for a smooth project run.

Processor—oriented work according to lSO is one of our standards. Our demand for optimal project realisation is often shaped by our customers requirements and contributes to a continual improvement process. GM-TECH, a professional mold tech china manufacturer, combine many years of interdisciplinary experience with innovative thinking for the optimal implementation of your new projects.

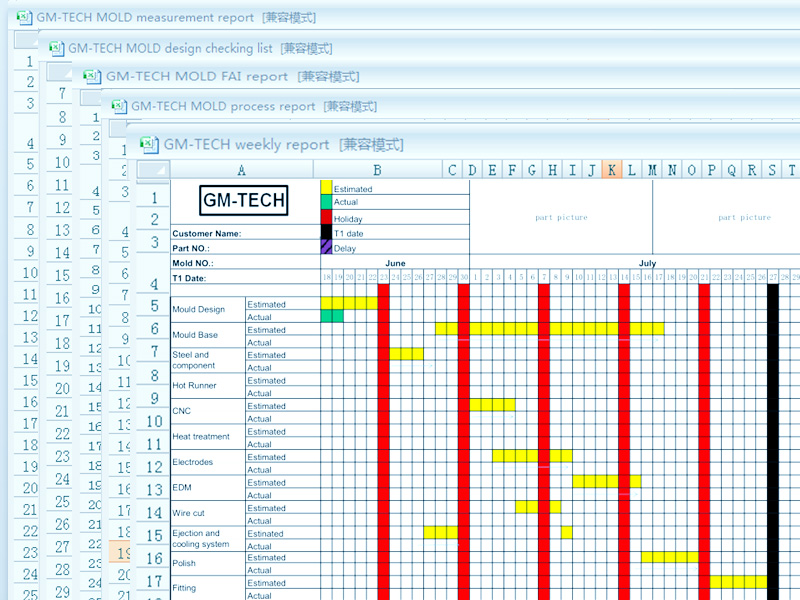

Our project management provides more than just timelines. Added benefits of our tracking program include:

Customer design review

Detail part design review

Preliminary mold product design review

Full design review

Development of the design & build timeline

Weekly timeline updates with photos showing progress

We will get started with part analysis once receive 3D data. We make mold flow analysis to find all the potential issues and send you the Moldflow analysis & DFM report.

We will make the mold specifications as per your mold requirements after receiving the purchasing order from our sales department and send it to clients for confirmation. It is better the customers provide us with specifications of mold design and mold manufacturing standards.

We will get started with 2D and 3D drawing when got the confirmation of the DFM report and the mold technical specifications.

The Tooling weekly report will be provided after getting the confirmation for the mold manufacturing. This Tooling weekly report will be updated every week as your requests the process photos.

This will be provided after the mold trail, and also with the 3 cycle trial out video and pictures showing the mold running status and samples' status.

Besides standard mold checking before shipment, water leaking checking is one of the most important work. Meanwhile, a complete mold file (2D drawing, 3D drawing, injection parameter, steel certificate, mold pictures, electrodes, etc.) will be shipped together with molds.

Call us on:

Call us on:  Email Us:

Email Us:  Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,

Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,