The categories of small household appliances mainly include: microwave ovens, rice cookers, electric irons, electric heaters, vacuum cleaners, electric fans, hair dryers, water dispensers, induction cookers, electric hot pots, electric kettles, air humidifiers, electric shavers, soymilk machines, juice extractor, coffee machine. So, how to choose home appliance plastic parts by high precision appliance plastic molding? Collected for everyone as follows:

1. Main materials used for appearance parts

ABS: high gloss, easy to spray, but not high temperature resistance;

PP: low cost, good fluidity, but poor dimensional stability;

PC: High strength, high temperature resistance, good transparency, but easy to crack;

PC/ABS alloy: Excellent overall performance, but higher price.

2. The main materials used for decorative parts

Transparent materials: transparent ABS, PMMA, PC, etc.

Electroplating material: electroplating grade ABS

Membrane material: PET film, PC film

3. Core requirements of 3C key components

Main materials: flame-retardant PBT, flame-retardant PP, flame-retardant PPO

4. The core requirements of other key structural parts

Main materials: POM, glass fiber reinforced nylon, PPS, PPA, PEI

1. Injection molded parts of microwave oven shell

The plastic parts on the microwave oven are mainly external parts, such as shell, mould base, handle, knob, etc., which require heat resistance.

The selected plastics are PBT/PET+GF, PBT+GF, PC/ABS, heat-resistant ABS, HIPS, heat-resistant PP, and PP.

2. Injection molded parts of rice cooker shell

The shell injection molded parts on the rice cooker are mainly external parts, including shell, base, cover, handle, switch, which require heat resistance. The selected plastics are ABS, high-gloss PP, and PP.

3. Injection molded parts of electric iron shell

The performance requirements of the plastic materials used for the injection molded parts of the electric iron shell are mainly heat resistance, followed by impact strength and appearance.

The shell, handle and sink base can be made of ABS, high-gloss PP;

The parts near the heating zone require high heat resistance. PC, PA+GF, PBT/PET+GF, PBT+GF, heat-resistant ABS can be used;

The heat resistance of the base is higher, and PBT/PET+GF, PET+GF can be used instead of metal parts.

4. Injection molded parts of electric heater shell

The common injection molded plastics materials used on the electric heater requires heat resistance, especially the outlet grille.

The selected plastic varieties are PBT/PET+GF, PET+GF, PC, PC/ABS, heat-resistant ABS, heat-resistant PP

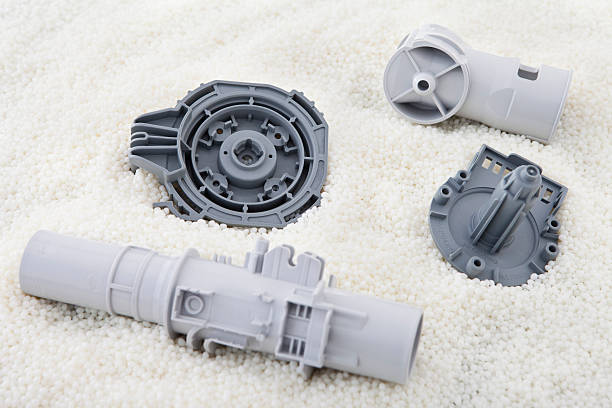

5. Injection molded parts of vacuum cleaner shell

The plastic materials used for vacuum cleaner components require anti-static to avoid dust absorption. In addition, they require good electrical performance, good rigidity, impact resistance, scratch resistance, good dyeability, and gloss, especially the housing.

The selected plastics are ABS, HIPS, and high-gloss PP. Among them, the transparent parts can be PC, AS, GPPS.

6. Injection molded parts of electric fan shell

The plastic parts used in electric fans mainly include fan blades, blade covers, shell covers, knobs and so on.

The selected plastic varieties are ABS, HIPS, high-gloss PP, PP+GF, AS+GF.

Call us on:

Call us on:  Email Us:

Email Us:  Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,

Shengan Building A, Hengzeng Road Chang'an Town Dongguan City,